Products

EMHA C3

Methyl ester from animal fatsUCOME

Used cooking oils methyl esterAdvanced biofuels

POME / SBEONE100

B100 by Nord-EsterByproduct

The by-product of transesterification: glycerine

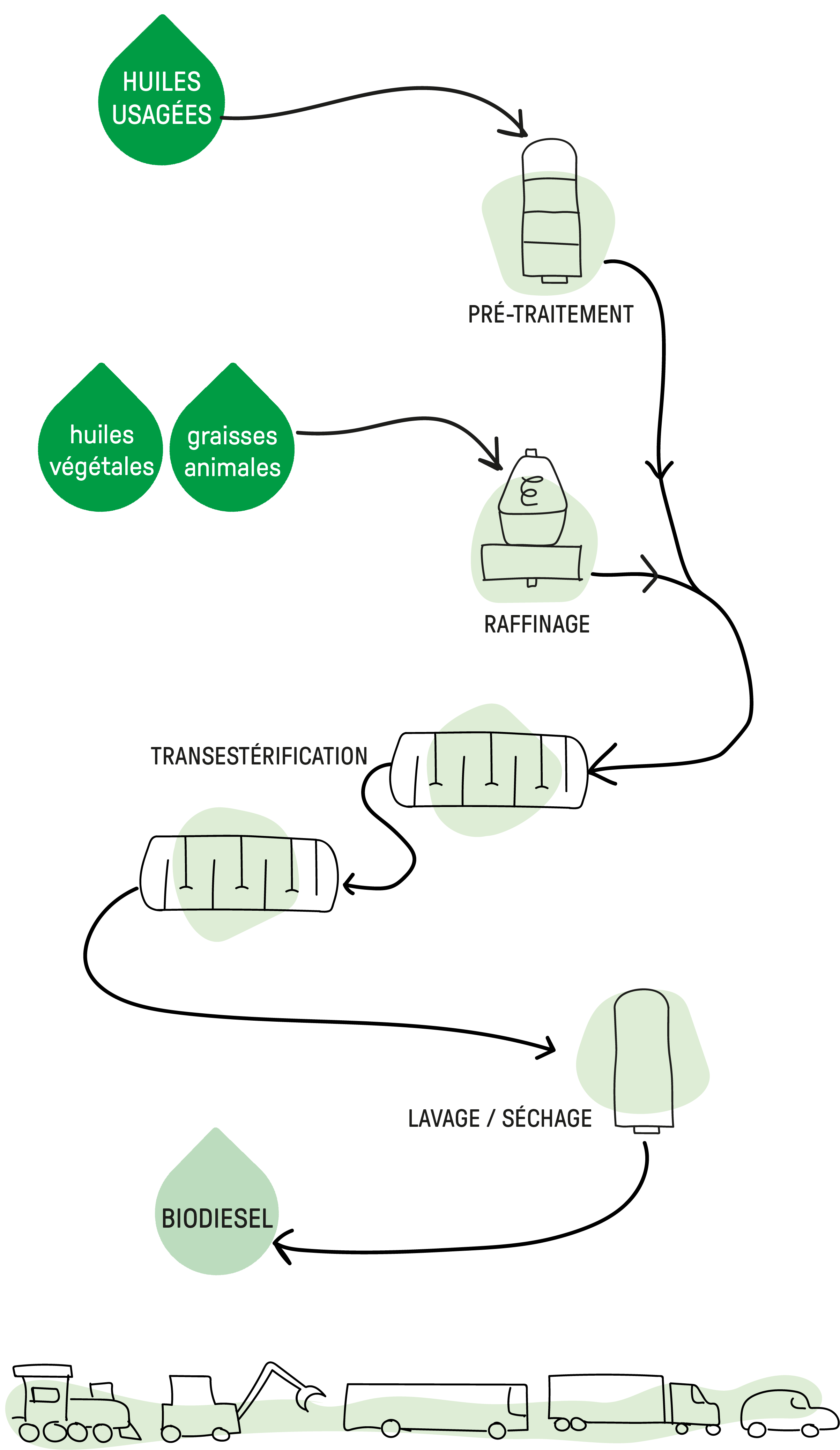

The transformation of fats into biodiesel is carried out via the transesterification reaction. This consists of reacting a fat with an alcohol to obtain a fatty acid ester.

Thanks to the know-how of our teams and our ability to innovate, we have upgraded our first-generation, 100% vegetable oil plant to a new generation biodiesel process. We have the capacity to operate at 100% with used oil.

This conversion is one of the first in Europe on an industrial scale. This development reflects our desire to give a second life to waste and not to compete with the food sector.

"We do not plan to increase our current production capacity. Our objective is to be reactive and to be able to adapt to more singular markets, especially when the requirements in terms of traceability are high."

Xavier

At the origin of the Nord-Ester project

In order to meet our CO2 reduction commitments, our boilers run solely on liquid biomass from our facilities.

A deacidification unit has been created by our technical services. This pre-treatment gives us the capacity to produce biodiesel from 100% used cooking oil.

Toutes ces années, Nord-Ester est restée fidèle à sa raison d’être. En tant que régulateur du marché, sa vocation est de consommer l’excédent agricole produit dans le monde. Cette démarche permet de soutenir les populations locales et les producteurs.

For more information about products and services :

Rue Georges Van Cauwenberghe

Zone Industrielle de Petite-Synthe

59640 DUNKERQUE

FRANCE

03 28 61 98 35

contact@nord-ester.fr

Réalisé par La Quincaillerie